Newsletter 03/2017

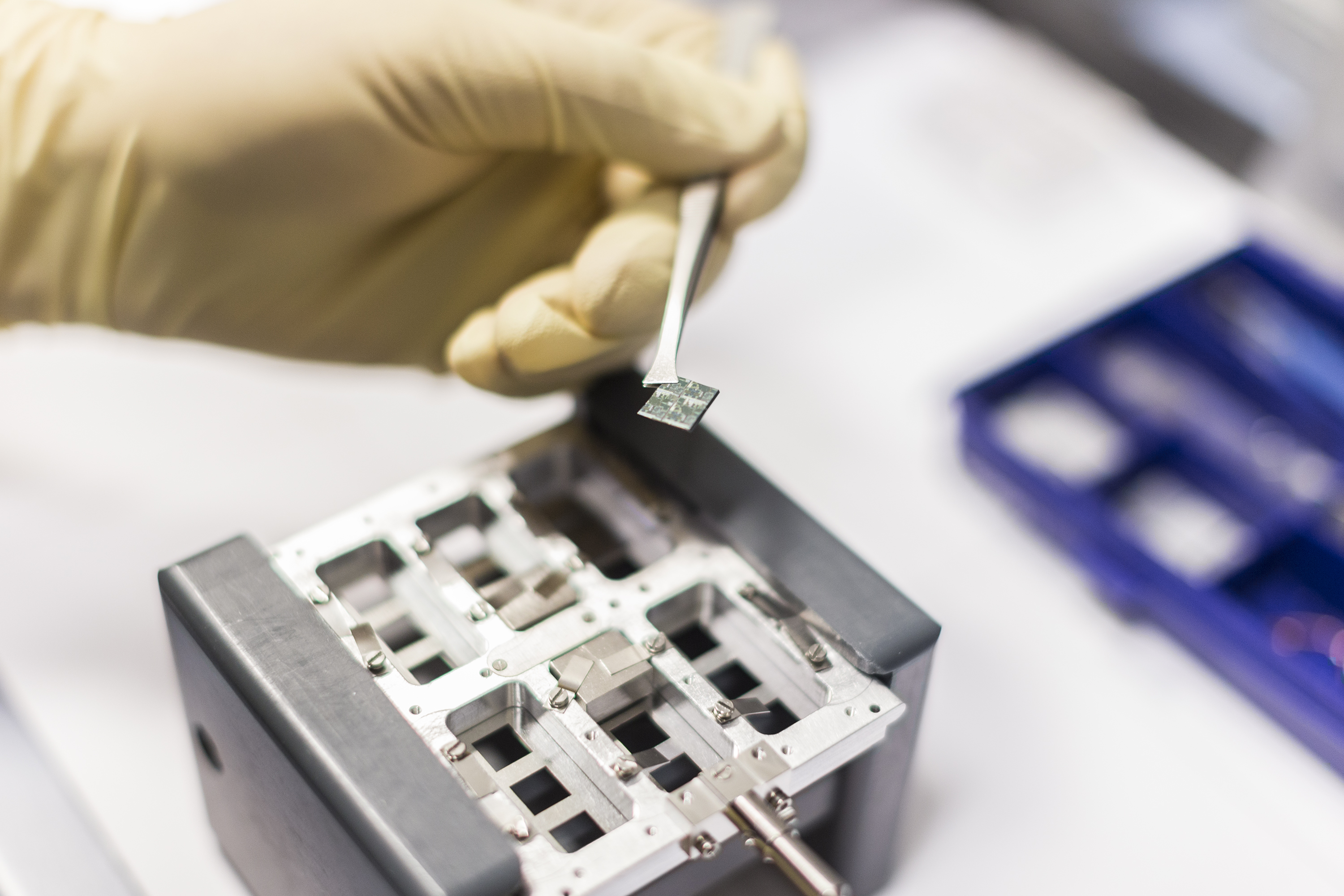

Over the last two years, Fraunhofer IIS/EAS and the semiconductor manufacturer GLOBALFOUNDRIES have worked together in the project »MARS« to advance the development of highly reliable 22 nm FDSOI components. These components should pave the way for »tactile intelligent systems« made in Dresden. Areas such as autonomous driving and applications in intelligent production will benefit enormously from such wirelessly networked systems capable of communicating with each other in real time.

Every second counts. In an age of increasingly networked applications, even this is far from sufficient. Many systems must respond reliably within mere fractions of a second while delivering particularly high levels of performance. And the demands are only rising. Examples of areas in which even faster applications will be required in the future include Car2X communication by autonomously driving vehicles and robot-assisted operations.

This will be made possible by the next generation of wireless real-time communication in what are called tactile intelligent systems (TIS). TIS are embedded systems characterized by real-time control, high computing power, numerous different sensors and actuators, high data rates and minimal latency. With TIS, devices are able not only of responding more quickly to signals from other systems, the environment or users; they can also act »reflexively«. This opens up the possibility of a completely new form of interaction and networking. The market potential is correspondingly great. Due to their extremely low latency of less than a millisecond, tactile intelligent systems are of particular interest in areas such as Industry 4.0, robotics applications, medical technology and automotive industry.

One milestone for TIS is the production-ready 22 nm FDSOI technology developed in Dresden by GLOBALFOUNDRIES. »With minimal energy consumption, our 22FDX components enable up to a hundredfold increase in the processing speed of radio-operated control and reception units,« explains Robert Seidel, project manager at the semiconductor manufacturer. »This is where the major advantages of our FDX power saving technology come into play – high performance with extremely low power draw. By using this in advanced applications such as TIS, we seek to help preserve and expand the innovative strength of Dresden as one of the leading locations in Europe for semiconductor technology.«

Because the GLOBALFOUNDRIES technology is intended primarily for use in safety-critical processes, 100-percent reliability must be guaranteed. The goal is to demonstrate that the components can do their work without issues even after extended periods of service. In the MARS project, Fraunhofer IIS/EAS has therefore worked on software tools, models and procedures that support the design capabilities and functional reliability of the 22FDX components. »The focus was on methods for simulations capable of verifying ten- to twenty-year reliability for the components,« explains Roland Jancke, who was responsible for the MARS work at Fraunhofer IIS/EAS.

This included researching new and informative aging models for the new components. »In contrast to earlier empirical models, these newly developed models are based on the actual physical effects. As a result, they permit predictions regarding the reliability under various usage conditions even before the first silicon is produced,« continues Jancke. Within the framework of the research project, the partners have been able to show that the prediction models and the initial measurement data already fit together well. More work is planned to take additional effects into account in the models. The MARS project ran for two years and received funding from the European Union and the Free State of Saxony within the scope of the European Regional Development Fund (ERDF).

Fraunhofer Institute for Integrated Circuits IIS, Division Engineering of Adaptive Systems EAS

Fraunhofer Institute for Integrated Circuits IIS, Division Engineering of Adaptive Systems EAS